The research team from Airlangga University, Surabaya, uses seaweed as a substitute for gelatin for capsule shell production. Its products are ready for mass production.

Capsule shell made from seaweed produced by Airlangga University, Surabaya.

The fulfillment for the need of capsule shells in Indonesia still depends on the raw material in the form of gelatin imported from abroad. The research team from Universitas Airlangga Surabaya then uses seaweed as a substitute for gelatin for capsule shell production. Its products are ready for mass production.

Within a year, the need for capsule shells for the domestic pharmaceutical industry reaches 6 billion eggs. About 5 billion of them are produced by domestic companies, but the raw material for gelatin comes by imports. For the rest, about 1 billion items are imported directly from the overseas pharmaceutical industry.

Although it can already produce capsule shells, gelatin as a raw material for its manufacture is still imported from Thailand, Bangladesh, and India. Gelatin is a hydrolysis product from collagen that comes from the skin, tissue, and bones of cattle, buffaloes, and pigs.

One of the impacts of gelatin import is the dependency of the domestic pharmaceutical industry because it does not have its own raw materials. Imported gelatin also cannot be guaranteed halal because some consumers want halal medicines, especially for consumers who embrace Islam.

This condition made researchers from Universitas Airlangga Surabaya conducted a research to find raw materials to replace gelatin. Starting from the thesis of the Department of Chemistry student, Faculty of Science and Technology, Universitas Airlangga in 2013, a number of researchers then developed it. Finally, about six years ago, Universitas Airlangga was able to produce capsule shells from seaweed.

A professor of Chemistry at Universitas Airlangga who was also one of the researchers, Pratiwi Pudjiastuti, said that seaweed as a raw material for capsule shells has a kappa-carrageenan compound that can replace gelatin. "The content of kappa-carrageenan in seaweed reaches 60 percent" She said in Surabaya, Monday (02/03/2020).

Seaweed as a raw material for capsule shells has a kappa-carrageenan compound that can replace gelatin.

The capsule shell of seaweed can also be ascertained halal. Because, the raw material comes from vegetable and the manufacturing process is closely monitored. This is different from imported gelatin from animals in which the halal status cannot be ascertained.

Source: research team of capsule shells from seaweed at Airlangga University, Surabaya Added value As an island nation with a coastline of 99,093 kilometers, seaweed production in 2017 reached 10.8 million tons. Most of the seaweed products are sold in the form of raw materials so that they do not have added value for Indonesian citizens.

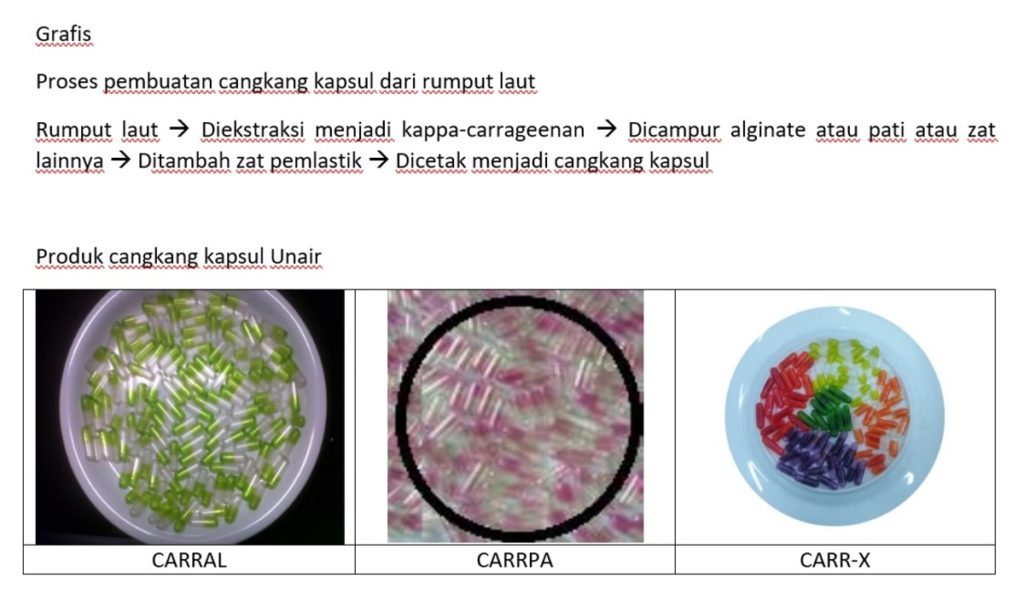

Pratiwi explained, to make capsule shells, seaweed must be extracted first. Then, the extraction results are mixed with other ingredients, such as alginate or starch according to the desired capsule shell character. The ingredients are mixed with plasticizers to be flexible and given additional substances.

"Raw material in the form of seaweed extraction is supplied from PT Kappa Carrageenan Nusantara in Pasuruan. We do not yet have a tool for extraction so that it is easier to obtain it from other parties" said Pratiwi.

At present, there are three types of capsule shells that Universitas Airlangga can produce. First, carral (carrageenan-alginate) which is a combination of red seaweed extract and brown seaweed. The character of this capsule shell that is released 12-14 minutes after consumption, is longer than the capsule shell of gelatin that can be released about 5 to 7 minutes.

This carral price is around Rp. 90 per capsule or three times more expensive than gelatin. However, the advantage of carral is very suitable for drugs that can not stand the acid can escape in the intestine, namely pH 6.8.

Moreover, the second capsule shell is carrpa (carrageenan-starch). This type of capsule shell is made from carral, but mixed with starch. Carrpa is developed to answer the weakness of carral which is expensive in production costs because it can reduce production costs.

This type of capsule shell is sold for Rp. 29 per item, the same as the capsule shell from gelatin. However, carrpa can only be released about 20-27 minutes after consumption or four times longer than the capsule shell of gelatin.

The long release time made the researchers continued to develop formulations to make capsule shells that were cheap and quickly detached, such as from gelatin. Finally, in 2017 the researchers perfected their product by adding a substance in carrpa raw material.

"The latest capsule shell called car-x has the property of being released faster and can be controlled by the time period of its release," said researcher from the Faculty of Pharmacy, Universitas Airlangga, Esti Hendradi.

The research team has a formula for regulating the time period for capsule release. It aims to maximize the function of the drug because there are several types of drugs that are more stable if released in certain organs such as the intestine, and not only in the stomach.

COMPASS / SAIFUL RIJAL SPECIALTY

COMPASS / SAIFUL RIJAL SPECIALTY

Nanang (60) seaweed fisherman dried the results of his cultivation in front of the residence, in Kokoe Village, Bombana, Southeast Sulawesi, Monday (9/23/2019). A number of capture and seaweed fishermen in this area have been working as miners in the past few years.

Teaching industry

At present, Airlangga has a capsule shell teaching industry made from seaweed which the construction began in 2018 at a cost of Rp 4 billion. The facility was built in collaboration between Universitas Airlangga University and the Ministry of Industry.

The production capacity of capsule shells in this place is around 3 million capsule shells per day and will be absorbed by the pharmaceutical company, PT Kapsulindo Nusantara. The capsule shell can last up to three years.

"The production cannot be operated yet because it awaits production permit, security permit, and certification. We hope that the permits will be issued soon so that this product can be mass produced immediately because all the equipment is ready," said Pratiwi.

Read also the Debate on Seaweed Network Culture

Another researcher from the Department of Chemistry, Universitas Airlangga, Siti Wafiroh, added, the capsule shell from seaweed has passed several stages of testing. Tests carried out include disintegration test to see the breakdown of the capsule shell, kinetic test to see the speed of the drug, and dissolution test to measure the speed of release and dissolution.

Like other industrial products, the manufacture of capsule shells from seaweed also produces waste. In one production process, there are around 30 percent of unused seaweed extracts. The waste comes from capsule dough which is not printed by capsule printing pinbar.

COMPASS / SAIFUL RIJAL SPECIALTY

Nanang (60), a seaweed fisherman, dried his crops in front of his residence in Kokoe Village, Bombana, Southeast Sulawesi, Monday (9/23/2019).

The waste can be reused to be processed into capsule shells. However, the utilization of waste can only be done for the second mold because the carrageenan polymer content is damaged if it wants to be reused.

However, the remaining waste from the second production can still be used as a substitute for plastic in the making of plates, cups, and straws. These products can be eaten after use because they do not contain harmful ingredients. If thrown away, the waste product can decompose by bacteria for about four days because it comes from organic matter.

"The utilization of seaweed adheres to the principle of zero waste because there is no waste that cannot be utilized. We hope there will be assistance for the procurement of machinery to utilize this waste," said Pratiwi.

Utilization of seaweed as a substitute for gelatin for capsule shell production should be supported by all parties. Licensing needs to be facilitated so that the benefits of research can be immediately felt by the community. The capsule shell from seaweed is one of the efforts of the nation's independence in the pharmaceutical industry.

author:

IQBAL BASYARI

10 Februari 2020

kompas.id