Ilustrasi by Pharmacy for Better Future

The speed at which the drug material dissolves or called as the dissolution rate is one of the factors that determines whether the drug material can dissolve quickly or if it actually takes place slowly. After the drug is dissolved, the drug will be absorbed by the body and provides the desired physiological effects. However, existing data indicate that more than 70% of medicinal ingredients are included in the category of low solubility drugs with high permeability or BCS class II. A low dissolution rate causes the drug to dissolve slowly so that the amount needed for absorption becomes small and is slowly available or may not even be reached so that bioavailability is low. One strategy that can be taken to improve the low dissolution rate is by making nanosuspension.

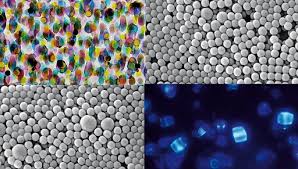

Nanosuspension is a nanometer sized drug crystal dispersed and stabilized in a stabilizer solution, where the stabilizers used can be in the form of surfactants (ionic, nonionic), polymers, or a combination of both. The selection of an appropriate stabilizer is one of the determining factors whether the particle size of the drug ingredient can be reduced to the nanometer scale, stable in the nanometer size achieved, and can have the effect of increasing dissolution rate.

However, in the initial stage, the selection of stabilizers requires a separate strategy, especially in terms of saving the amount of drug ingredients used. This is important especially for medicinal materials that are still developing and not yet available on the market. Broadly speaking, there are two methods of making nanosuspension that can be applied, namely: (1) high pressure homogenization (HPH); (2) and wet beads milling (WBM).

WBM method is preferred because in addition to producing nanosuspension with smaller size (up to <200 nm) compared to HPH, on a laboratory scale this method can be done with simple equipments such as magnetic stirring plates, magnetic stirrers, and milling beads. The particle size reduction process is the same, based on continuous impaction and attrition so that the particle size can be reduced. However, it is important to ensure that the size of the nanoparticle obtained at the laboratory scale will be the same as the result at a larger scale.

To answer this, a study was carried out using two different medicinal ingredients which had difficulty to dissolve properties, namely curcumin and hesperetin. Each drug ingredient was stabilized with a different stabilizer. Curcumin was stabilized with a combination of sodium cholate - poloxamer 188 each 1.7% w / w while hesperetin was stabilized with poloxamer 188 by 2.0% w / w. At the laboratory scale, WBM was carried out to make 10 g of curcumin nanosuspension and hesperetin nanosuspension with the help of magnetic stirrer and ytrrium stabilized zirconium beads of 0.5 mm size.

Milling was carried out for 5 hours and produced nanosuspensions with sizes of 190 nm for curcumin and 165 nm for hesperetin. On a further scale of 120 g, it was made using high energy wet beads milling (HE-WBM), performed at the same nanosuspension composition, the same grinding duration but at 2 different speeds. At a speed of 1000 rpm, curcumin nanosuspension was 151 nm and an increase in velocity with the same duration resulted in a smaller nanosuspension particle size of 114 nm.

The same pattern was also shown by the hesperetin nanosuspension, where a speed of 1000 rpm produced a particle size of 160 nm and a speed of 2000 rpm produced a particle size of 112 nm. Next, it was made on a scale of 2 kg using the HE-WBM re-circulation method with speeds of 1000 rpm and 2000 rpm. At a speed of 1000 rpm, the nanosuspence of curcumin and the hesperetin nanosuspence showed a larger particle size than the particle size at the laboratory scale and HE-WBM 120 g. An increase in milling speed of 2000 rpm could produce particle sizes the same as the laboratory scale and 120 g scale.

Based on the results obtained, magnetic stirrer and milling beads for the optimization and production of nanosuspension on a small scale (10 g) gave predictive results and were not different from the results at the time of making nanosuspension at a larger scale with tools that had greater energy capacity. This showed that the use of relatively simple magnetic stirrers and milling beads could be used in the initial stage of optimization of nanosuspension manufacturing.

Author : Dr.rer.nat. Maria Lucia Ardhani Dwi Lestari, Apt

Detailed information of this research can be accessed on our article here: http://www.eurekaselect.com/171179/article

Maria L.A.D. Lestari, Rainer H. Müller, Jan P. Möschwitzer. 2019. The Scalability of Wet Ball Milling for The Production of Nanosuspensions. Pharmaceutical Nanotechnology, Volume 7 , Issue 2.